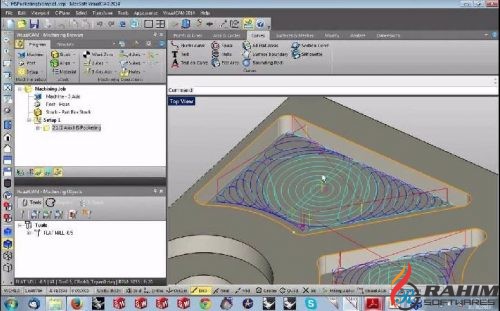

MecSoft.VisualCADCAM.2017.v6.0.419 MecSoft Corporation, the developer of industry leading CAD/CAM software solutions, has released 6.0.387 version of VisualCAD/CAM 2017 the latest version of their flagship standalone CNC programming software. VisualCAM along with VisualCAD is MecSoft's standalone CAD/CAM package that is considered the best valued CAD/CAM system on the market today. CNC Controller; VisualCAD/CAM. VisualCAM; RhinoCAM; VisualCAM for SOLIDWORKS; 5 Axis Gantry Type CNC; Double Column CNC; CNC Machining Center. Vertical CNC; Dental Milling; CNC Cutting system; Adjustable Steel Gantry Crane Shop Lift; News. 2017 Taipei International Industrial Automation Exhibition; 27th Taipei Iny'l Machine Tool. Download the VisualCAD/CAM Demo; Download the VisualCAM for SOLIDWORKS Demo; Download Visual3DPRINT 2016; Download Visual3DPRINT 2017; Download Visual3DPRINT 2017 Demo; Download VisualART 1.0; Download VisualCAD/CAM 2014; Download VisualCAD/CAM 2016; Download VisualCAD/CAM 2016 Demo; Download VisualCAD/CAM 2017; Download VisualCAD/CAM 2018. Watch this demonstration of FreeMILL, the cost-free milling plug-in included with VisualCAD/CAM 2019. Get more resources at Enjoy!

NC Software on the PC Controller is included with every machine.

Autoscale Routers and Hot Wire Cutters use standard G-Code language. Our machines will run most tool paths from almost every CAM software company. To utilize the full length of the Z axis all tool paths must be generated in a minimum of a 3+2 World Coordinate System. Please feel free to send us a test file to run a simulation.

Here is our complete list of MecSoft CAD/CAM software options available with a Autoscale Router.

Rhino 5 for Windows can be purchased along with RhinCAM together at our store.

RHINOCAM PRO 2020

RhinoCAM is a CAM Software plug-in that runs completely inside of Rhinoceros 5.0 & 6.0 (Windows only). RhinoCAM marries the power of Rhino’s freeform modeling with the legendary CAM functionality of VisualCAM to bring you a product of unrivaled capability. With seamless and complete integration RhinoCAM, acts and feels like you are working with Rhino when generating CNC programs. RhinoCAM is also fully associative to any geometry changes within Rhino.

RhinoCAM is fully associative to any geometry changes within Rhino. RhinoCAM includes modules for MILL, TURN, NEST, and ART to address specific needs of various CNC manufacturing processes.

Visual Cad Cam 2017 Torrent

VISUAL MILL for SOLIDWORKS PRO 2020

VisualCAM for SOLIDWORKS® is based on our industry leading VisualCAM Software that is fully integrated in SOLIDWORKS 2010 thru 2017. From simple 2-1/2 axis to full 5-axis continuous milling, VisualCAM for SOLIDWORKS will help you make parts, fast. VisualCAM 2017 for SOLIDWORKS also an add-on TURN module.

This family of products offers several options to fit your machining needs and are fully integrated with SOLIDWORKS, offering an intuitive combined user interface for CAD and CAM, fully associative toolpath updates, and a wide variety of post processors. Compared to a stand-alone CAM system, VisualCAM for SOLIDWORKS will save you countless hours by automatically updating toolpaths when your model changes. And being integrated with SOLIDWORKS means you only have one interface to learn, saving even more valuable time.

This fully associative parametric CAD/CAM system makes VisualCAM for SOLIDWORKS one of the most cost effective and powerful systems in the market today.

VISUAL CAD/CAM PRO 2020

VisualCAM along with VisualCAD is MecSoft’s standalone CAD/CAM package that is considered the best valued CAD/CAM system on the market today. VisualCAD/CAM features MecSoft’s FREE and easy-to-use CAD program VisualCAD, which is the host platform for the VisualCAM and Visual3DPRINT plug-in products.

VisualCAM is MecSoft’s flagship CAM product that addresses the CNC machining market needs with modules VisualMILL, VisualTURN, VisualNEST, and VisualART to address specific needs of various CNC manufacturing processes.

MecSoft Corp.’s CAMJam 2018 is a video training companion for the company’s VisualCAD/CAM, RhinoCAM, VisualCAM for Solidworks, and AlibreCAM milling modules.

Edited by

Read Next

MecSoft Corp.’s CAMJam 2018 is a video training companion for the company’s VisualCAD/CAM, RhinoCAM, VisualCAM for Solidworks, and AlibreCAM milling modules. It consists of a video archive of training sessions conducted by company support staff, including all videos from the 2017 version, as well as updates for 2018.

Don LaCourse, senior application engineer at MecSoft, says, “We’re very excited about our new CAMJam 2018 video archive. It builds upon previous versions and now includes videos on all of our CAM modules including Mill, Turn, Nest and Art. It also includes five-axis milling and multi-axis robot machining, and links to our Learn CAD/CAM blog series.”

Mecsoft Visualcad/cam 2017

Key features of the archive include over 60 instructional videos, a PDF document that enables video retrieval and access to all of the source part files referenced in the videos.

The archive covers a range of topics. It discusses automatic feature machining tools, what’s new in 2018 and best practices in 2½-axis and three-axis machining. It also addresses machine setup, stock and geometry considerations, and indexed five-axis setups. Two- through five-axis machining strategies are covered, as well as creating user defined form tools for custom 2½-axis profiling operations. The archive features videos on postprocessor generators; setup for multiple axis milling; implementing custom tool libraries and rules-based machining knowledge bases; implementing user-specific defaults databases; using machining regions and control geometry; and viewing, simulating and editing toolpath operations.

RELATED CONTENT

How to Slash 5-Axis Finishing Time

Finally there is an alternative to ballnose endmills for finishing 3D parts. The combination of finishing tools shaped to provide more cutting surface and a CAM system with the ability to apply them on a five-axis machining center can dramatically reduce finishing cycle times while delivering better surface finishes.

Transferring CAD/CAM Files

Importing and exporting CAD files is a fundamental function of CAM software. An understanding of this process can help you know what to expect and will aid you when making a CAM purchase.

There Are Apps For That, Too

These two iPhone apps provide manufacturing professionals and students with quick access to helpful cutting tool information directly from their smart phones.